Dear fellow warehouse practitioners,

We start this edition of our BLOG with a set of 4 questions.

DC stands for Distribution Center.

Please, answer the following 4 questions.

1.

My DC is boxed-in with poor slotting, poor labor productivity

a.

Yes

b.

No

2.

We know how to improve our performance. We don’t need any outside help.

a.

Yes

b.

No

3.

But we cannot do anything, because we are in a jam.

a.

Yes

b.

No

4.

We do not have any funding to make large scale layout changes

a.

Yes

b.

No

Just in case, you have answered “YES” to all the 4 questions, join the vast majority of DC’s across the Logistics World that share your feelings.

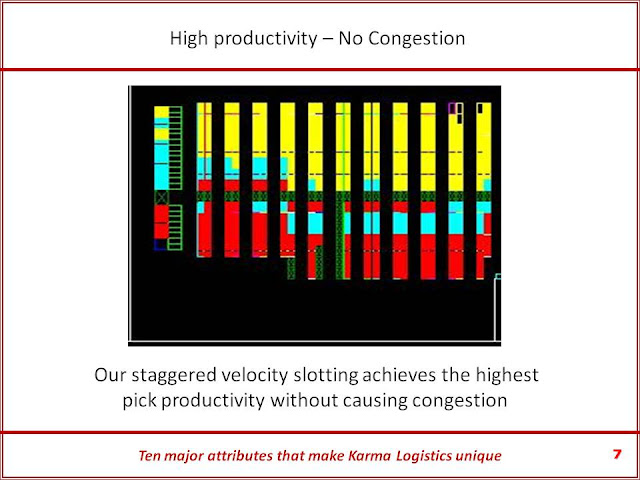

We all know that a good layout and slotting cuts down travel time and increases productivity.

Where do we go now for more improvement? How can we improve our performance with ZERO capital funds available? We are assuming that you have some ‘operating funds” available

Do you have slotting situations like the 2 above pictures in your DC?

Picture on the left: an extreme case of bad slotting.

Picture on the right: Innovative use of reserve storage. Putting 3 small pallets one on top of the other.

In this graphic, the green color represents the CROSS BEAM. The most common length of this cross beam is 96” and the vertical thickness is usually around 4” to 6” (in the US). But you can buy these cross beams in any length and thickness you want.

We will be discussing the rest of this article about these cross-beams and how they influence the vertical height of the slot (and the total cube of the slot).

When the DC was first constructed or when it was last remodeled, the location of these cross beams were assigned.

Flexible versus Optimum – which is better?

Designing Flexibility in a design comes with a cost. The rack design shown above [left most] is a Flexible design. You are able to fit a wide variety of products. Often such a slotting scheme will maintain a clearance of 60” in each level. But, you get only 3 levels.

Optimum design

The rack design shown above [right most] can be considered as an efficient design, tailored to the needs of the current inventory. It has 7 levels. Compared to just 3 levels in the Flexible design.

Which is better?

We don’t know. We must examine different options and actually fit the existing inventory. Is that the design shown in the middle.

Karma Logistics is introducing a new technique to find the Best-fit slot openings for your DC and at the same time, maintain a degree of flexibility. If you are interested in improving your cube efficiency and hence the picking productivity, please contact us.

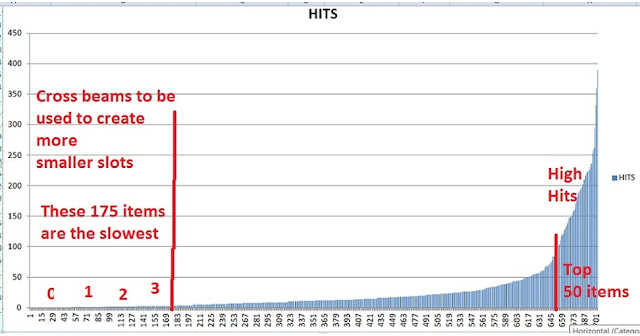

Where do we start?

We first analyse your current slot openings.

Our analysis will prepare a list of all the slot openings you have. And this will be compared against the correct number and types of slot openings we need.

As we prepare the slot moves and the slot adjustments, we will emphasize FAST MOVERS located in a bad area plus slotted in a wrong slot size. But before that, we will work on your SLOW ITEMS occupying PREMIUM SLOTS. We will first move the SLOW movers. This will create empty slots. We then look at FAST movers and move them to the SLOTS of the correct size in the premium locations.

Before we conclude this BLOG, we want to restate an old axiom for DC's.

The picture below is an attempt to show a DC made up of ICE BLOCKS. Instead of having real products, pretend that they are all made up of similar sized ice blocks.

[See picture below]

Now pretend that it is a hot day in June and the outside temperature is over 90 degrees F.

And all the ice blocks have melted. And we carefully collected all the melted water and stored them over the warehouse floor.

Question: How high will this water be, from the floor?

Answers: 1. 20 feet high. 2. 15 feet high 3. 10 feet high 4. 2 feet high 5. 11" high

The correct answer is closer to 11" high.

Why look at CUBE efficiency?

We only pick cases. But our asset is really CUBEs.

Using the Karma Logistics technique,

1.0 we will help you find the correct sizes and numbers of slots.

2.0 we will make sure that the available cases in the pick slots will support a certain days of sales demand.

3.0 this will reduce the number of 'mark outs' and 'partial picks'

4.0 will help organize and streamline the replenishment process

5.0 Plus of course, we will slot the item based on its movement and other characteristics.

Contact:

Karma Logistics Inc

Ram.Krishnan@yahoo.com

Minnesota USA

Bangalore India