We all try to do the best with forecasting, just-in-time (JIT)controls, vendor managed Inventory VMI etc.

But most of these are great concepts. Ideally, a customer goes to a retail store, buys a bottle of shampoo. That information reverberates backwards through the supply chain, all the way back to the manufacturing and they produce a brand new bottle of that shampoo.

This never happens in reality. We have factors called EOQ, economic order quantity, OPS – optimum production schedule, transportation consolidation, etc. This gets worse in a large country like the US, with a coast to coast distance of 5000 miles. This may work well in Japan, probably about the size of one of the states in the US.

When the Detroit auto industry commenced the JIT program, all their suppliers moved to Detroit, put up their final assembly plants within 20 to 30 miles from Detroit, thereby creating a ‘mini-Japan’.

But in most warehouses across the US, we typically end up with ‘incorrect quantities’ of incorrect SKU’s” at incorrect times.

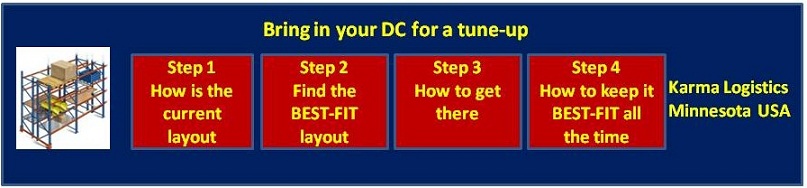

In the picture above, we have superimposed the ABC color codes (A – red, fast, B- blue, medium, C-yellow, slow) over an existing layout. In the above layout, products are received on the right hand side, and shipped on the left hand side.

What do you see in this picture? Which color tends to dominate the picture?

Yes, it is the YELLOW color, The slow moving sku’s.

We have coined a new term F.I.S.H (pronounced as fish). It stands for First In Still here. Is it ok to say that the above picture looks like a sea of dead FISH interspersed by few jewels of red (A) and blue (B) slots

By the way, every FISH item was the result of a bad forecast or a bad something. That is just the nature of things. We cannot blame anyone or anything

We display 2 slots. One contains a popular item. The other slot contains a slow or FISH item. Each slot takes about 4 feet of front width.

At 200 orders/day,

8 lines / order, 4 feet per pallet,

Extra distance = 6,400 ft / day,

At 200 Feet/Min, 32 mins/day,

133 hrs/yr, $ 12/hr, $ 1,596 /yr

Walking past 1 slow or dead pallet - costs about $1,596 per year

The $ number 1,596 is for illustration. Every DC has different stats. Round this to $ 1500.

this is a annual number.

* Every time someone walks or drive past one of these FISH items, you should tell yourself. Oops, I see a $ 1500 opportunity for the company.

* Then internally ask yourself, how many such $ 1500 is in my facility.

* This calculation will vary for everyone. Say your net profit margin is 5%. (Too high a number in the US). That means to earn $ 5 of net profit; you need to sell $ 100 of products.

Now, how many sales $ you need to offset $ 1500.

Multiply by 20. You get $ 30,000.

Now pretend that you have 100 such dead fish items.

Now you need $ 3,000,000 of sales.

For these 100 really smelling dead fish items, if you cannot predict $ 3 million in NEW sales in a tough market, PLEASE throw these 100 items into the nearby garbage. Don't tell your accountants about it. Accountants may be happy counting anything.

You will really get a 'breadth of fresh air' after getting rid of the dead fish.

And guess what? You will have more room to work with the 'few pearls' you have.

Additional costs

INCLUDE cost of storage of those 100 sku’s – space, utility, investment (carrying finance) cost of the 100 sku

What to do with those items?

What to do with those items?

1.0 Put them in trash, when the accountant is not around and call it a ‘inventory shrink’.

2.0 OR take all those cases – consolidate them into very few pallets, stretch wrap them, slot them in the highest level of your racks, deep in the rear most side the warehouse.

3.0 In many product sectors, we may have a sub-channel of distribution that does not clash with the main channel. Like a ‘outlet store’.

Karma Logistics offers a co-market, co-consuting job opportunity.

Please see the link below to see the details.